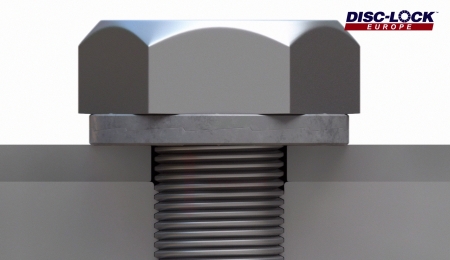

Disc-Lock’s superior fastening systems are used across a wide range of industries where vibration is an issue.

Our washers and nuts are heavy-duty structural locking devices recommended for the most stressful, dynamic applications. From trucks and trailers to mining equipment and heavy machinery - Disc-Lock products provide a fit and forget solution.

The system is a simple one. Interlocking cams rise against each other to create a wedging effect that locks the assembly together and maintains tension. Joint integrity is guaranteed and once installed, the fastener remains fully secure with no need for retightening.

The ultimate wheel security on our roads